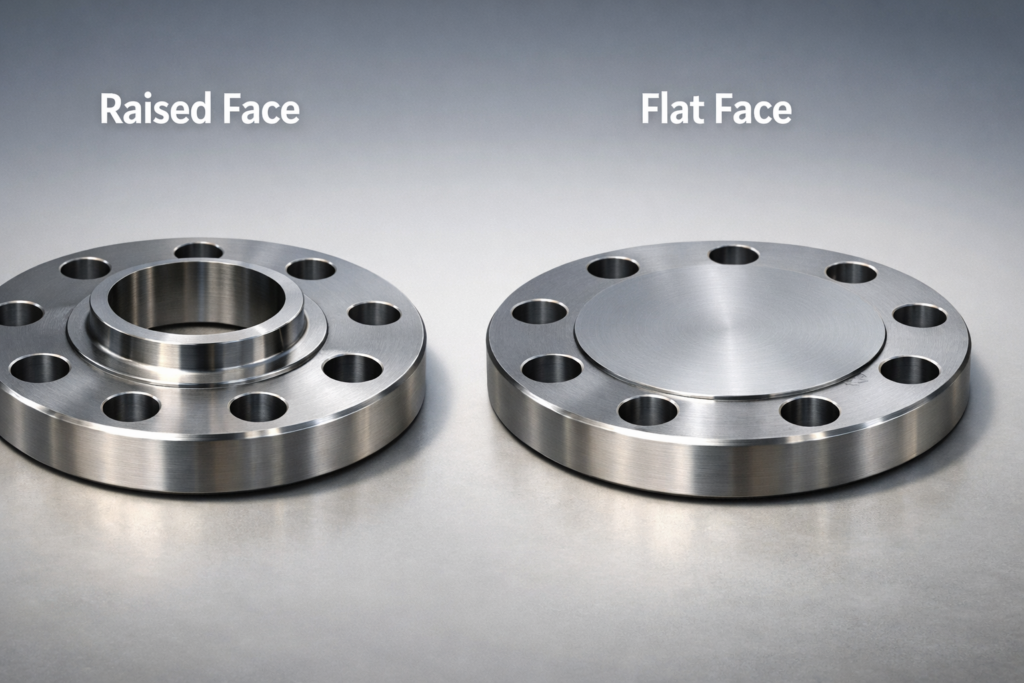

In any industrial piping system, the connection point between flanges is a potential leak source. The design of the flange face, the surface that mates with the gasket, is critical in preventing this. Among the various types standardized by ANSI/ASME B16.5, Raised Face (RF) and Flat Face (FF) are the two most common. Selecting the correct one is not a matter of preference but a fundamental engineering decision that affects safety, reliability, and cost. This guide explains their key differences and provides clear guidelines for proper selection.

At a Glance: Key Differences

The table below summarizes the core distinctions between Raised Face and Flat Face flanges.

Understanding Raised Face (RF) Flanges

Design and Standards

The defining feature of an RF flange is a raised, serrated ring encircling the bore. According to ASME B16.5 standards, this raised face is 1/16 inch (1.6 mm) high for pressure classes 150 and 300, and 1/4 inch (6.4 mm) high for classes 400 and above. The serrated finish (typically 125-250 micro-inches) helps grip the gasket.

How It Works: The Principle of Concentration

The key advantage of the RF design is mechanical efficiency. By reducing the contact area to the raised ring, the bolt torque is concentrated on a smaller gasket area. This creates a much higher sealing pressure (force/area) with the same bolt load, enabling a tight seal against high internal pressures and temperatures.

Common Applications

- Oil & Gas Production and Refining: Handles high-pressure hydrocarbons and gases.

- Petrochemical Plants: Seals corrosive and high-temperature process fluids.

- Power Generation: Used in high-pressure steam and feedwater lines.

- General High-Pressure Process Piping: The default choice for most severe service conditions.

Understanding Flat Face (FF) Flanges

Design and Rationale

A Flat Face flange has no raised section; its sealing surface is completely level. This design is primarily used to protect brittle flange materials. When a brittle material like cast iron is bolted to a Raised Face flange, the concentrated load from the raised ring can create a bending moment, leading to cracking or fracture at the bolt holes.

How It Works: The Principle of Distribution

The FF design uses a full-face gasket that covers the entire surface from the bore to the outer edge, including holes for the bolts. When tightened, the bolt load is distributed evenly across the full face of the flange. This eliminates point stresses and prevents the cracking risk associated with brittle materials.

Critical Installation Rule

A fundamental rule in piping is that a Flat Face flange must never be bolted directly to a Raised Face flange. The gap created by the raised face will place extreme bending stress on the FF flange, likely causing it to fail. If connecting carbon steel (RF) to cast iron (FF), the raised face on the steel flange must be machined flat to create a uniform FF-FF connection.

Common Applications

- Low-Pressure Water Systems: Municipal water, cooling water, and drainage.

- Fire Protection Piping: Sprinkler and hydrant systems.

- HVAC Systems: Chilled and heating water lines.

- Piping with Brittle Materials: Systems using cast iron, fiberglass, or certain plastics.

Note: For high-quality industrial flanges used in piping and fabrication, visit Texas Flange, a trusted flange manufacturer specializing in precision-engineered flange solutions.

Gasket Selection and Installation Best Practices

The flange face choice dictates the gasket type, which is integral to a leak-free joint.

- For Raised Face (RF): Use ring-type gaskets (e.g., spiral wound, metal jacketed, Camprofile) that fit inside the bolt circle. The serrated finish of the flange face bites into these gaskets for an excellent seal.

- For Flat Face (FF): Use full-face gaskets made of non-metallic materials like rubber, EPDM, or compressed non-asbestos fiber. These gaskets have bolt holes and cover the entire face.

Proper bolt torquing is non-negotiable for both types. Always follow a star-pattern tightening sequence and achieve the specified torque in multiple passes to ensure even gasket compression and avoid warping the flanges.

FAQs – Frequently Asked Questions

1. Can I use a Raised Face flange for low-pressure water applications?

Yes, it is technically possible and often done, especially if the rest of the plant standardizes on RF flanges. However, a Flat Face flange with a full-face gasket is typically more cost-effective for these services.

2. What happens if I accidentally bolt a Flat Face flange to a Raised Face flange?

This is a serious error. The Flat Face flange, especially if made of a brittle material like cast iron, will be subjected to uneven bending stress. This can lead to immediate cracking or a latent failure, resulting in a dangerous leak.

3. Are there other flange face types besides RF and FF?

Yes. Ring-Type Joint (RTJ) faces have a groove for a metal ring gasket and are used for very high pressures (Class 600 and above). Tongue-and-Groove (T&G) and Male-and-Female (M&F) are used for specialized applications requiring precise alignment and sealing.

4. Does the surface finish of the flange face matter?

Absolutely. A serrated (machined) finish is required to provide a “bite” on the gasket material and create an effective seal. A smooth, polished surface would be more prone to leakage.

5. Where can I find the exact dimensions for these flanges?

The complete dimensional data for ANSI/ASME RF and FF flanges, including outside diameter, bolt circle, and raised face height, is defined in the ASME B16.5 standard for sizes up to 24″ and ASME B16.47 for larger sizes. For a broader understanding of specifications, you can refer to our guide on ANSI flange specifications.

Conclusion

The choice between a Raised Face and a Flat Face flange is a foundational decision in piping design. Raised Face flanges are the high-performance option, engineered to contain extreme pressures and temperatures by concentrating sealing force. Flat Face flanges serve a vital protective role, ensuring the integrity of systems built with brittle materials by distributing load evenly.

Always base your selection on the flange material first, then consider pressure, temperature, and service fluid. Following the standards and respecting compatibility rules—most importantly, never mating RF to FF—is essential for building safe, reliable, and leak-free piping systems.